Topcoats

Enrich the functional scope of basecoats.

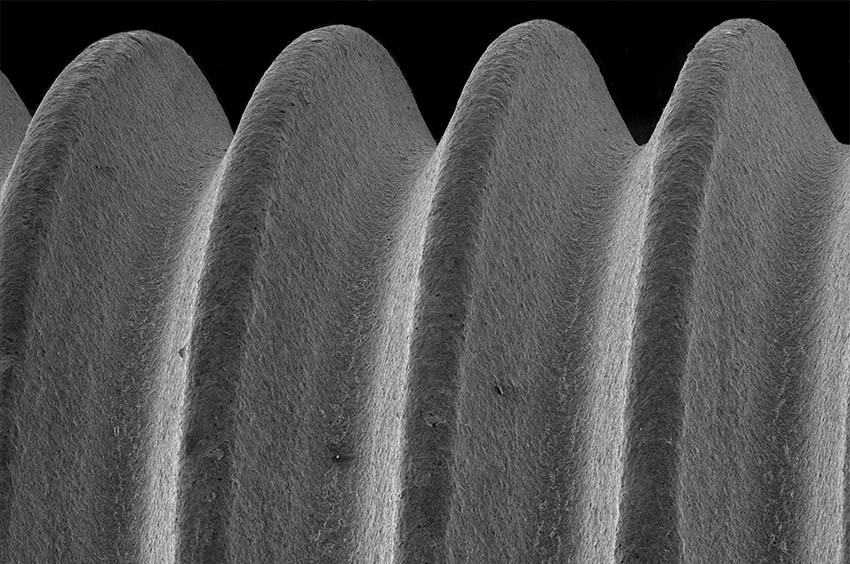

Designed to perform at low thicknesses, our topcoat technologies are formulated to offer many functionalities: controlled friction, chemical resistance, increased corrosion resistance, temperature resistance, color, etc. They are the result of our chemists’ know-how and experience in selecting and combining the most adapted resins, lubricants, additives and pigments.

-

PLUS®

GEOMETPLUS® / DACROMETPLUS®PLUS® are water-based topcoats with a silicate resin. This type of resin increases the corrosion protection of the parts, including bimetallic corrosion.

Formulated with lubricants, some PLUS® topcoats offer outstanding tribological properties on different bearing materials, especially for threaded fasteners (no stick-slip effect, stability under multi-tightening, stability under high-speed tightening).

-

DACROLUB®

DACROLUB® are water-based topcoats made of organic thermoplastic binders and lubricants. This combination ensures controlled friction on different bearing materials.

-

ECHOTE®

ECHOTE® are water-based topcoats that can be applied on our base coats. Their unique resin film improves the chemical resistance of parts exposed to acid, alkalin etc. environments. They are also used for outdoor exposure and bi-metallic corrosion applications by various industries.

-

P®

P® Series topcoats are water-based coatings designed to provide outstanding solvent and chemical resistance while enhancing the corrosion performance of zinc-rich basecoats. This series of coatings is available in multiple lubricity levels designed to meet the most demanding installation needs.

-

LTX®

Our product portfolio

- Career

- Quality Policy

- Environment Policy

- Privacy Policy

- Website terms of use

- Cookies management panel

- © NOF Metal Coatings Group 2025