PLUS® ML

1-5 µm

Lubrication

- * Measured on GEOMET® 321 or GEOMET® 720 on HM10.

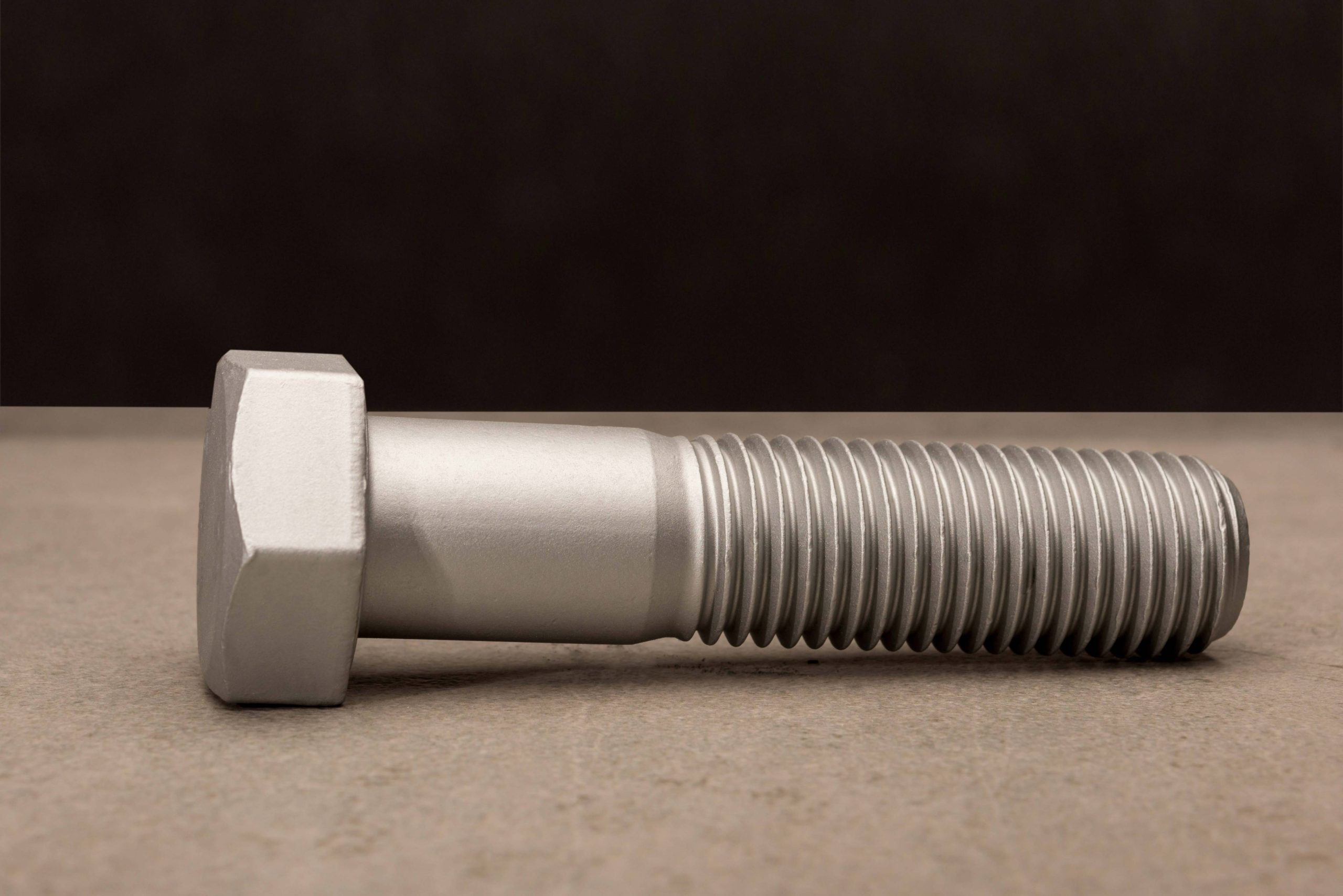

Combined with our zinc flake basecoats, PLUS® ML reacts and creates a barrier effect that improves both the corrosion resistance of the system and the contact corrosion with aluminum and other materials.

Resistance to industrial solvents and automotive fluids.

PLUS® ML can be colored for part visual identification and differentiation.

PLUS® ML can be functionalized with a UV tracer for part visual identification and differentiation.

Implemented via non-electrolytic application processes. This avoids the hydrogen embrittlement phenomenon that causes cracking of metals.

Processes

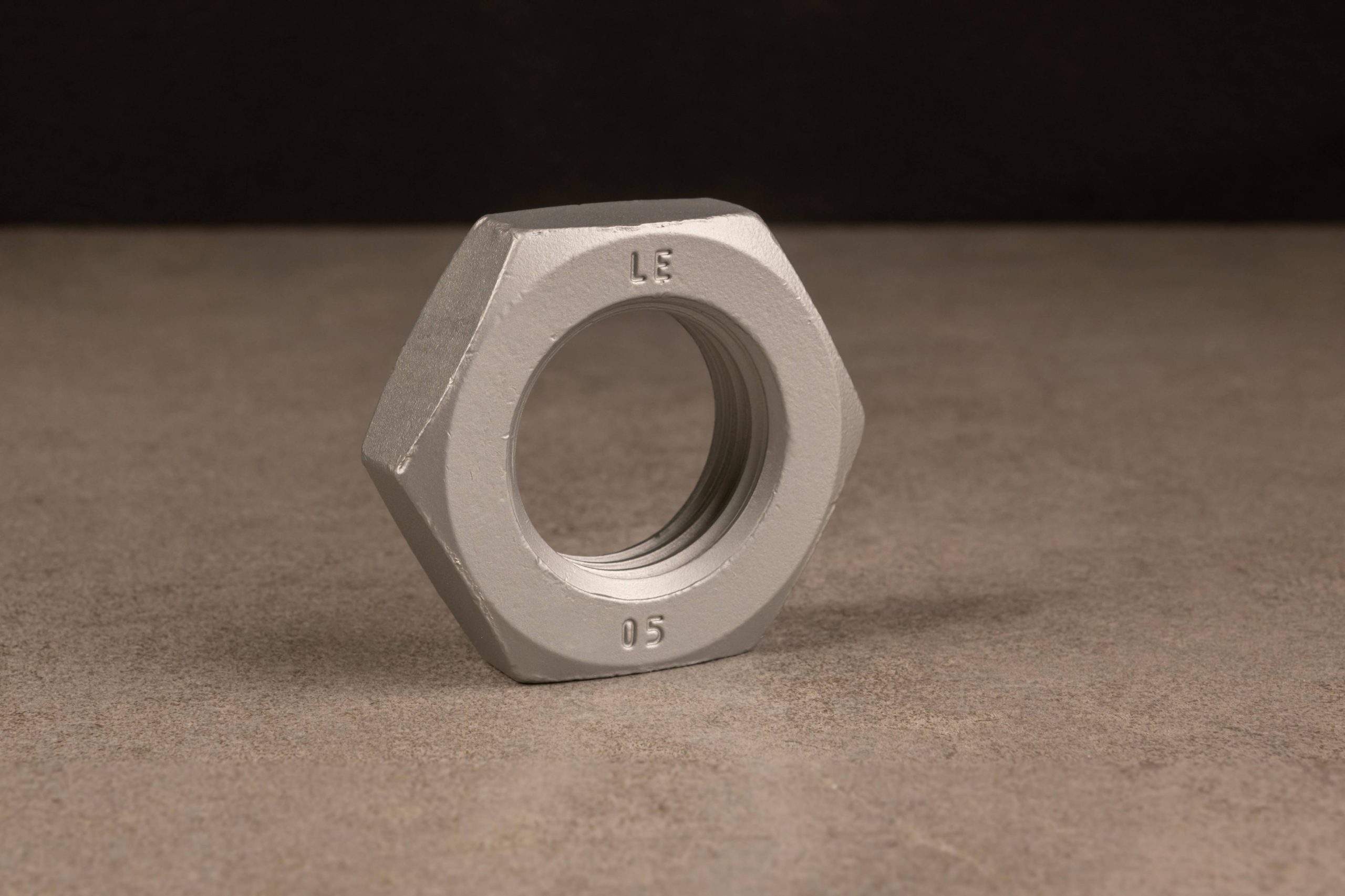

PLUS® ML is applied via bulk dip/spin, rack dip/spin, spray or electrostatic spray. This variety of processes allows to coat all types of parts, even those requiring partial coating, or with recessed and hollow surfaces. Moreover, they are non-electrolytic and thus avoid the phenomenon of hydrogen embrittlement which causes cracking of metals.

Waterborne silicate

PLUS® ML is a technology composed of lubricants in a silicate resin. It has been developed to comply with the highest industrial requirements and regulations regarding environment, health and safety. It is water-based and nonylphenol-free.

pds/plus-ml/en/2026-02-03/