-

Corrosion protection

Our basecoats contain zinc and aluminium flakes in an inorganic binder matrix. The coating protects the metallic substrate of the part by a combination of electrochemical reaction and barrier effect. Our solutions are also used in various applications to prevent galvanic corrosion.

The standard versions of our coatings reach systematically a NSS resistance greater than 720h and pass the demanding climate tests of the automotive industry. More sophisticated solutions are specified above 1.500h NSS, or even several thousands of hours for multilayer systems.

Our products

-

Friction control

Using a dry lubricated topcoat or a basecoat with integrated lubrication results in a friction coefficient for threaded parts within varying friction windows of small tolerances starting from 0,06 - 0,09 up to 0,20.

Controlled friction of the coated elements ensures the correct pre-tensioning of the joint, prevents heat loosening and avoids stick-slip effects in automated assembly situations.

Our products

-

No hydrogen embrittlement

Our coatings are implemented via non-electrolytic application processes. This avoids the hydrogen embrittlement phenomenon that causes cracking of metals and, ultimately, the failure of the affected components. That's why our solutions are suitable for safety and high-strength steel parts.

Our products

-

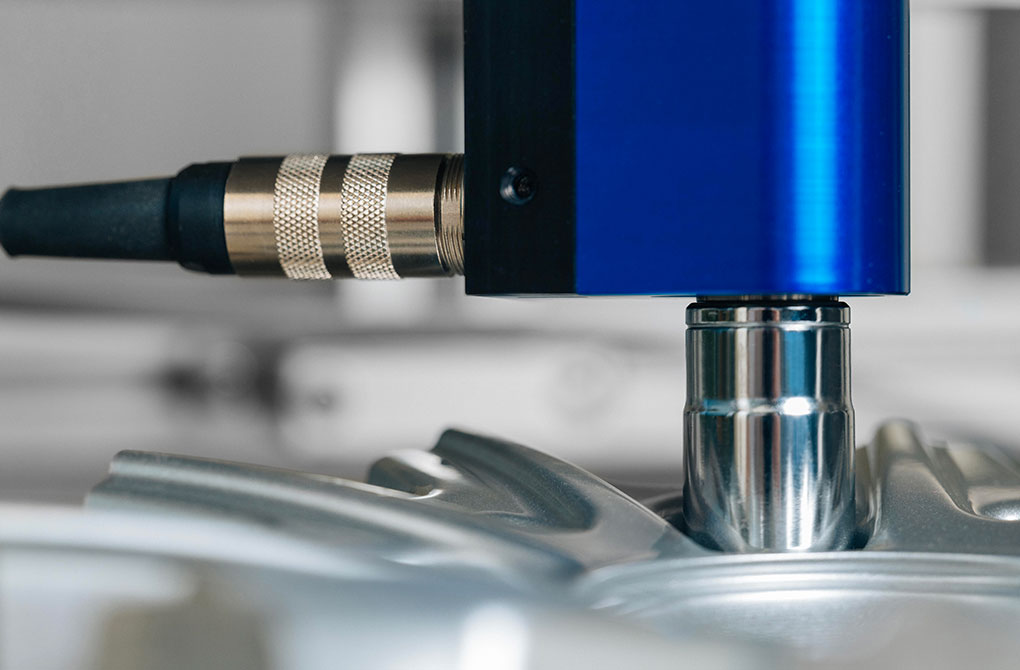

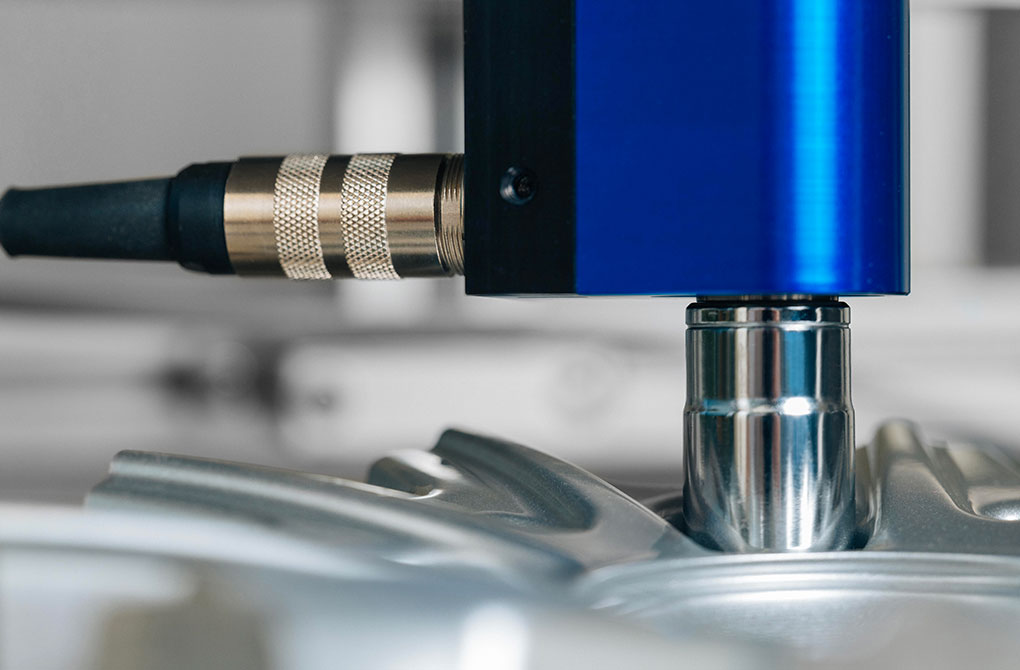

Low thickness

Our coatings are designed to provide high performance at low thickness (around 10 µm). This range of thickness is particularly adapted to allow perfect gaugeability for fasteners and for a large range of mechanical assemblies.

Our products

Silver and black are the standards colors for basecoats.

Excellent surface and adhesion conditions for additional paints or coatings.

Resistance to acids, bases, industrial solvants, fertilizers and automobile fluids.

Performances maintained at elevated service temperatures and in case of thermal shock exposure.

Our basecoats provide high static friction coefficients against various material surfaces, such as aluminum, steel, organic coatings or galvanized parts. As a result mechanical assemblies are more robust and less clamp load is required for joint solutions.

Topcoats can be colored or functionalized with a UV tracer for part visual identification and differentiation.

Our basecoats are conductive and offer perfect galvanic properties to avoid bi-metallic corrosion in most of industrial assemblies (stainless steel, cast iron, carbon steel and aluminum alloys). For more challenging conditions, additionnal insulating topcoats are needed to further protect against galvanic corrosion.

Our coatings are implemented via non-electrolytic application processes. The entire surface of the part can be coated, even the recessed and hollow areas.

Explore our product portfolio