A PFAS-FREE future for NOF Metal Coatings Group

WHAT ARE PFAS?

PFAS, or poly- (or per-) fluoroalkyl substances, form a large group of over 10,000 fluorinated compounds renowned for their anti-adhesive, waterproof and heat-resistant properties. Widely used since the 1950s in a variety of industrial sectors and everyday products, PFAS – often referred to as “the forever chemicals” – are now coming under increasing scrutiny due to their long-lasting presence in the environment and toxicity.

REGULATORY SITUATION

The European Chemicals Agency (ECHA) is advocating a European ban on PFASs based on REACh, to come into force as early as 2027 for specific industrial segments. Meanwhile, in the USA, the Environmental Protection Agency (EPA) is actively examining PFASs and proposing regulations specifically targeting water contamination. Although a total ban is not expected in the USA, global supply chains will be impacted by the implementation of REACh regulations.

Consequently, Asia and South America are also proactively preparing for the elimination of PFAS in order to safeguard and enhance their global production and import capabilities.

NOF METAL COATINGS IMPACTED PRODUCTS

NOF Metal Coatings Group is determined to contribute as soon as possible to the reduction or elimination of all substances that have a negative impact on the environment.

Apart from PTFE, a fluoropolymer currently classified as a “polymer of low concern” by the Organization for Economic Co-operation and Development (OECD), we do not use any other PFAS in our products. However, PTFE may be impacted by proposed restrictions.

It is specifically used in some of our lubricated products:

- GEOMET® 500* [0.12-0.18 (ISO 16 047)]

- PLUS® XL & XL Black [0.06-0.09 (ISO 16 047)]

- PLUS® VL [0.09-0.14 (ISO 16 047)]

- PLUS® VLh & VLh Black [0.09-0.14 (ISO 16 047)]

- PLUS® ML & ML Black [0.10-0.16 (ISO 16 047)]

- PLUS® L [0.08-0.14 (ISO 16 047)]

- PLUS® BLACK 500M [0.11-0.17 (ISO 16 047)]

*For those seeking alternatives to GEOMET® 500, we recommend considering GEOMET® 321 + PLUS® M as an immediate substitute.

All our other products are entirely PFAS-free, including:

- GEOMET® 321

- GEOMET® 360

- GEOMET® 720 & 720 HP

- GEOMET® 430

- PLUS® [0.14-0.20 (ISO 16 047)]

- PLUS® 10

- PLUS® M [0.12-0.18 (ISO 16 047)]

- …

ENVIRONMENTALLY FRIENDLY COATINGS

Driven by a deep commitment to evolution, sustainable practices and environmental responsibility, NOF Metal Coatings Group has always looked for innovative solutions to reduce its impact on the planet. In fact, as pioneers in the development of water-based zinc flake coatings, we have always prioritized environmentally friendly alternatives. That’s why, in response to the growing awareness of the threat posed by PFAS, we have already initiated a transition to PFAS-free products.

PFAS FREE FUTURE

Regardless of potential restrictions imposed by environmental authorities on PTFE, we will offer a PFAS-free product generation.

To achieve this ambitious goal, we have established a dedicated and international task force including R&D, environmental expertise, and market insight. This transversal and international team ensures a comprehensive approach to the development process.

The research and the selection of alternatives to PTFE have focused on raw materials that comply with high environmental standards and that are available worldwide to guarantee the uniqueness of formulations on all continents.

Beyond the sustainability, inherent to this project, we are seizing the opportunity to align our technical requirements on a global scale and to establish rigorous guidelines for the development of our PFAS-free range to build a more global and rational product offer, able to meet industry expectations but also to anticipate upcoming challenges.

Our PFAS-free topcoats will be available in black and silver, the clear versions will be maintained in Asia. This improvement promises a far more aesthetic result on parts.

SEAMLESS TRANSITION

Identical performance will be maintained to ensure a consistent product experience when switching to this PFAS-free range.

Notably, the PFAS-free alternative to PLUS® VLh and PLUS® ML will satisfy the requirements of VW 011 31, MBN 105 44, GMW 3359 and will have the same outstanding:

– behavior in loosening tests (including at high temperature), multi-tightening and high-speed tightening,

– stick slip avoidance,

– compatibility with various counterpart materials (e-coat, aluminum, and steel).

We will also be working closely with our network of licensees, parts manufacturers, and OEMs to minimize the technological impact of this transition.

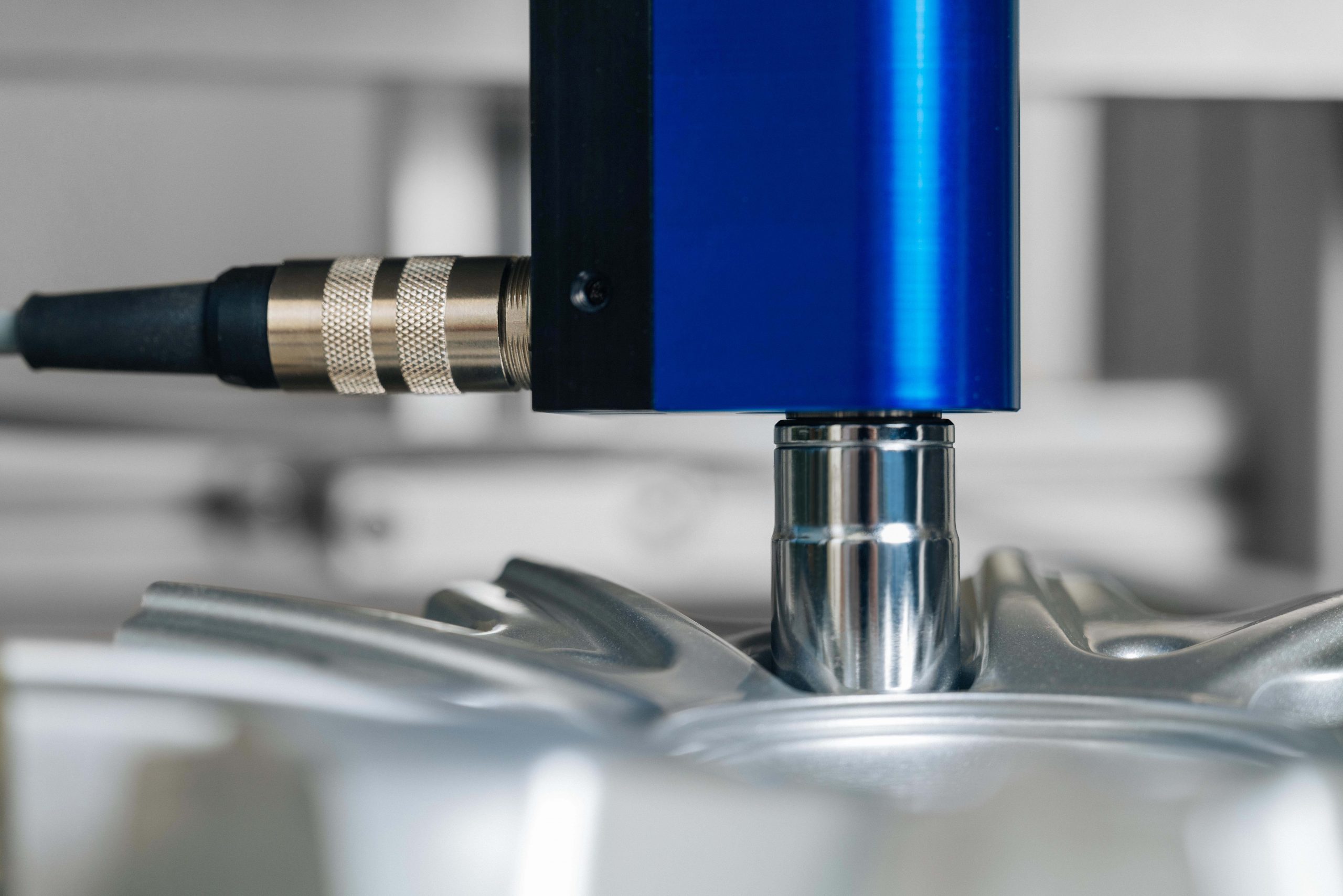

Extensive testing under real-life industrial conditions will be carried out to guarantee:

– their good applicability, under identical conditions, at our licensees’ plants,

– a level of reliability comparable to the one of our current products,

– that all the test criteria defined in OEM specifications are met.

WHAT’S NEXT?

As a leading supplier of zinc flake coating technology, we are fully aware of our responsibility to support the global fastener industry in addressing the potential challenges posed by a PFAS ban. Our forward-looking development approach positions us to offer PFAS-free products in the very near future.

The industrialization process of the PFAS-free alternative to PLUS® VLh/ML/XL will be initiated in close collaboration with fastener manufacturers and OEMs, our partners in the supply chain.

Sampling and testing at fastener manufacturers are already ongoing, and approval processes at OEMs will be initiated starting Q1/2024.

Stay tuned for more news as we continue to develop greener and more sustainable coating solutions.