Parts

-

Metric screws

Our systems provide excellent multi-tightening performance vs. steel, e-coat, aluminum, and no warm loosening to optimize manufacturing costs in OEMs plants. High corrosion performance and no hydrogen embrittlement are a perfect match for high grade bolts.

-

Wood screws

Our specially developed coating system provides wood screws with the lubricity necessary for fast and smooth fastening to the timber, as well as excellent chemical and corrosion resistance.

-

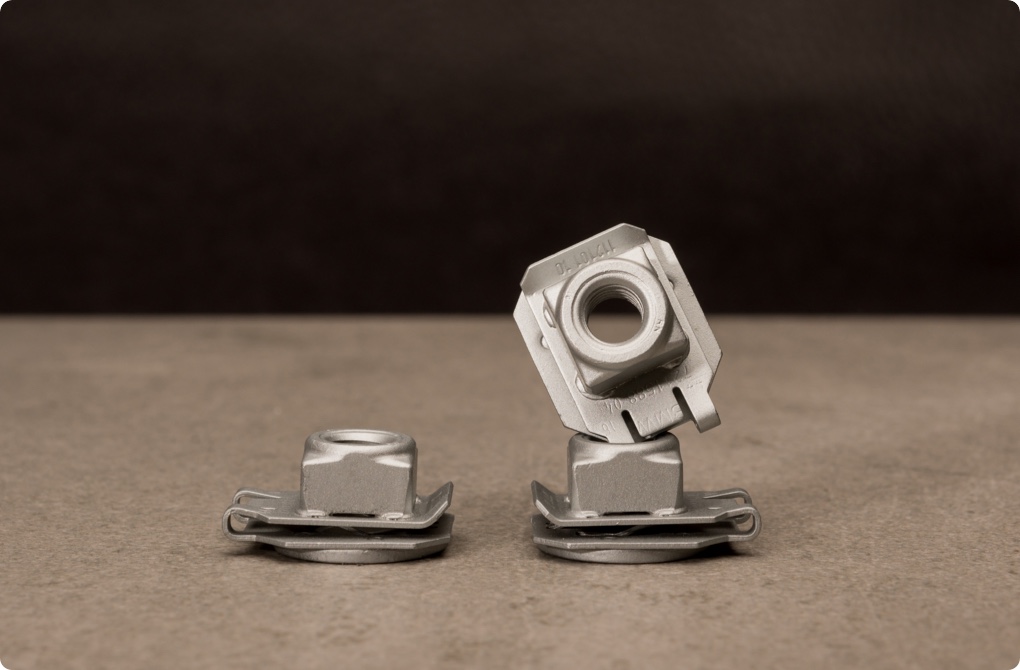

Nuts

High functionalities (anticorrosion, tightening, …) can be achieved with appropriate coating process to keep gaugeability in the internal thread.

-

Washers

Adapted coating process allows to coat washers and benefit from high corrosion resistance and adapted friction in combination with screws to compensate potential issues with substrates variability. Coating ductility is sufficient to cope with elastic deformation from washers.

-

Springs

Various springs are coated with GEOMET® by our licensees. Coating ductility is sufficient to cope with elastic deformation from springs.

-

Hose clamps

Our systems fulfill technical requirements from various OEMs. For specific requirements (high ductility, galvanic compatibility), we develop systems with specific topcoats. For instance, PLUS® 10 is used to insulate GEOMET® to protect further from galvanic corrosion (e.g., hose clips on carbon rich rubber) for specific OEMs.

-

Ball studs

They need high corrosion resistance and controlled friction but at the same time no coating on the functional ball area that will be assembled with housing. Partial coating done at our licensees allows to achieve the required performance.

-

Clips

Clips must provide an easy and quick assembly in OEMs or Tier 1 plants. Our key benefits are anti-corrosion after assembly and appropriate lubrication performance to improve introduction and extraction forces from clips.

-

U-Bolts

U-bolts are used within vehicle suspension to connect leaf springs providing a lasting attachment to the axle. High anti-corrosion and lubrication performance are key for these safety parts which are coated either in spray or rack dip-spin.

-

Studs for wind energy

These studs are used for on-shore and off-shore wind turbines. Durability is a key point to keep safety in use and avoid high maintenance costs. These studs are coated in rack with superior corrosion protection (>1500h).

Brake system

Find the coating that meets your requirements

From the choice of coatings and application processes to their industrialization, our teams put their know-how at your service to guide you towards the solution that fits your parts.

- Career

- Quality policy

- Environmental policy

- GDPR policy

- Privacy policy

- Terms of use

- Terms of sale

- Cookies management panel

- © NOF Metal Coatings Group 2025