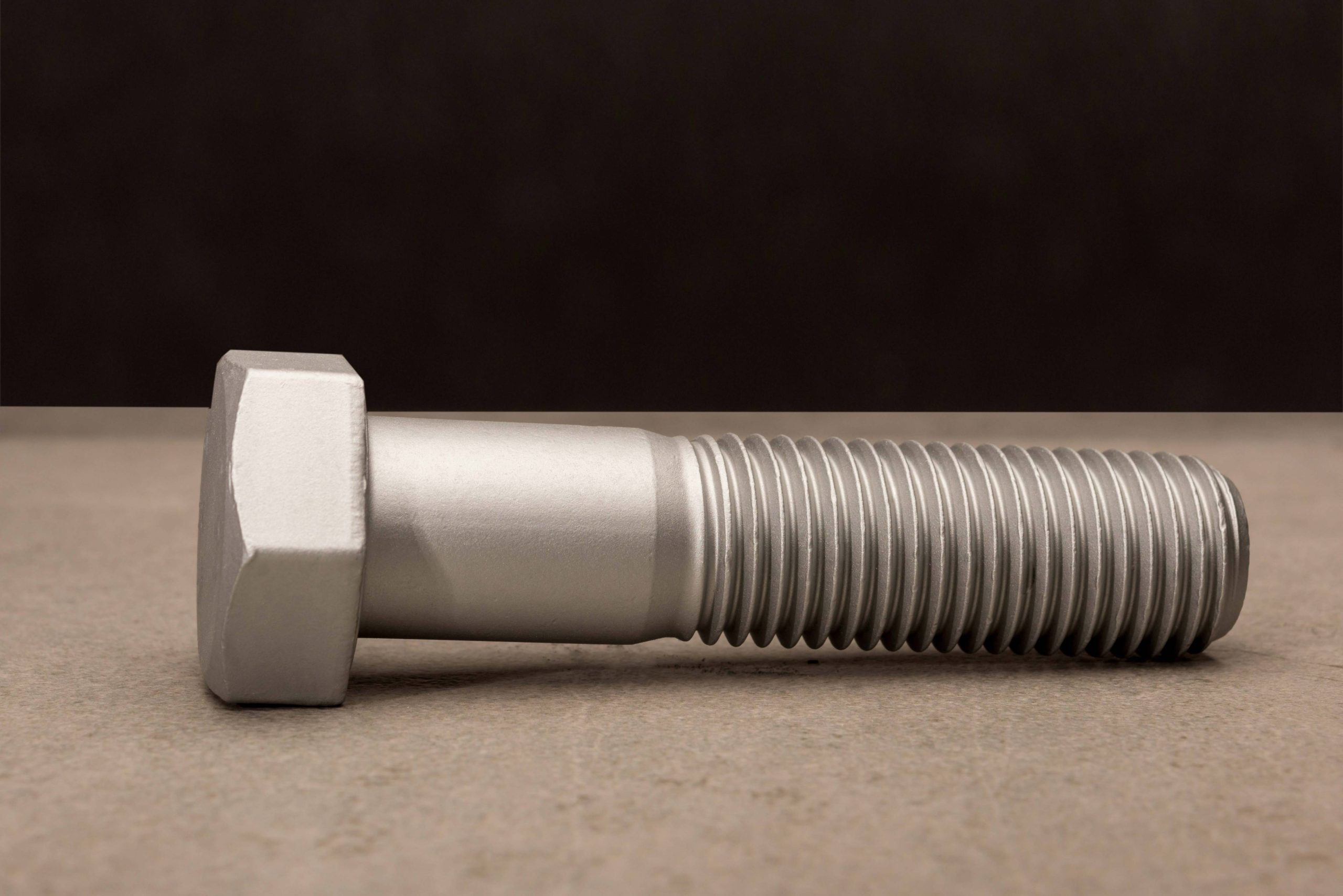

GEOMETPLUS® KL Clear

1.11±0.03 g/㎤

3~6 g/㎡

- * 20℃, Density Cup

Lubrication

- * Measured on GEOMET® 720 &HP

Combined with our zinc flake basecoats, GEOMETPLUS® KL CLEAR reacts and creates a barrier effect that improves both the corrosion resistance of the system and the contact corrosion with aluminum and other materials.

Resistance to industrial solvents and automotive fluids.

Processes

GEOMETPLUS® KL CLEAR is applied via bulk dip/spin, rack dip/spin.

Waterborne silicate

GEOMETPLUS® KL CLEAR is a technology composed of lubricants in a silicate resin. It has been developed to comply with the highest industrial requirements and regulations regarding environment, health and safety. It is water-based and nonylphenol-free.

pds/geometplus-kl-clear/en/2025-05-13/